Material Handling Conveyor System Manufacturers in Mumbai, Suppliers and Exporters in Mumbai

Worldmap Autocontrol System is the leading material handling conveyor system manufacturers in Mumbai, suppliers and exporters in Mumbai. Our systems are made using cutting-edge technology and efficient tools.

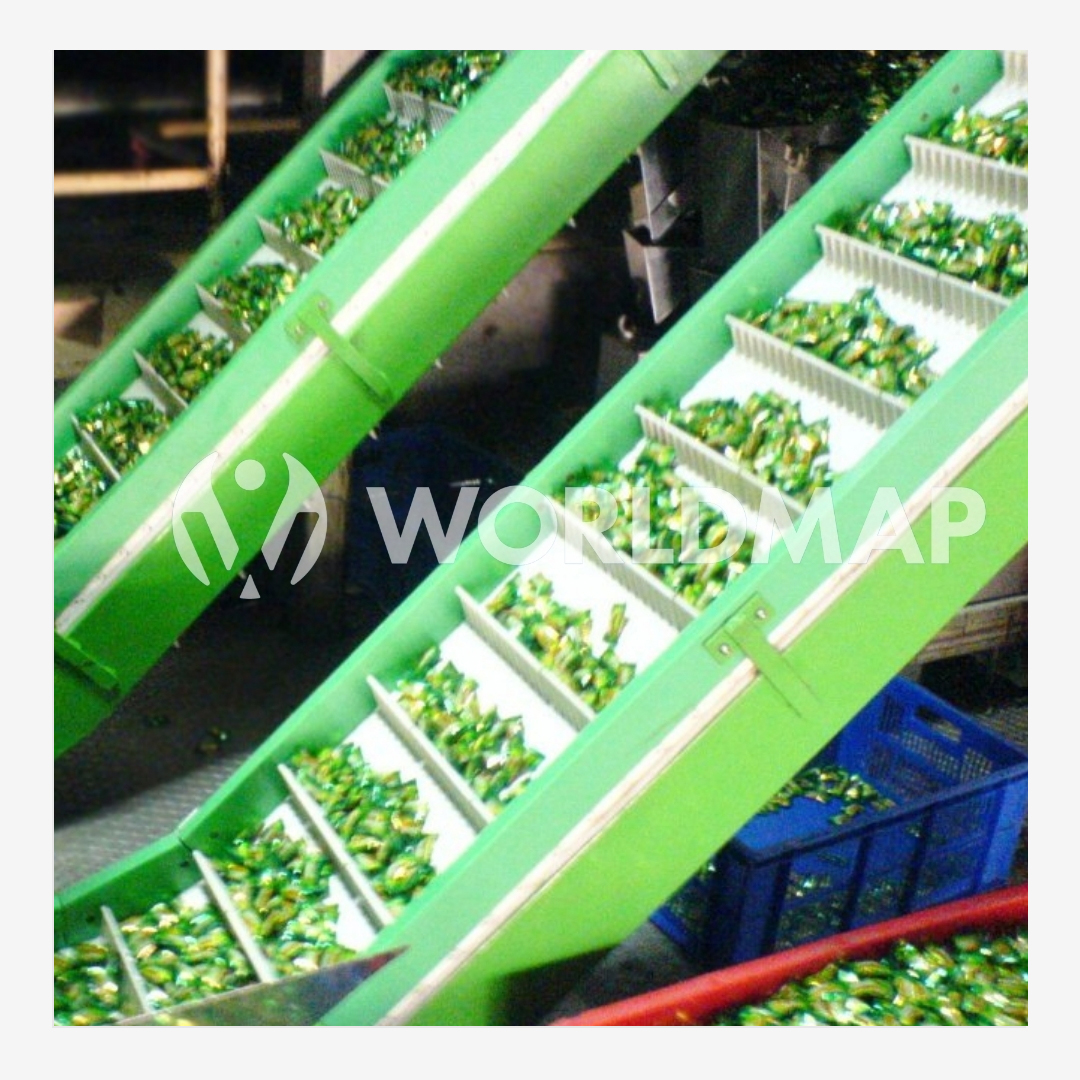

The material handling conveyor systems are made up of multiple conveyors with varying components designed for transporting materials. These systems carry out various tasks such as moving materials, loading, unloading, sorting, and distributing over extended distances.

Types of Material Handling Conveyor Systems:

As a material handling conveyor system suppliers in Mumbai, we offer these systems in different types.

- Pneumatic Conveyor Systems: This system uses air pressure or vacuum for movement of the materials along with a system of pipes or tubes. It works well for transporting large quantities of substances over long distances. The system generates an airflow that moves the materials through the pipeline and makes transportation in both horizontal and vertical directions. One major benefit of pneumatic systems is that they can decrease the need for material handling and lower the chances of contamination. These systems can be customized for a variety of materials and speeds, and are suitable for diverse uses.

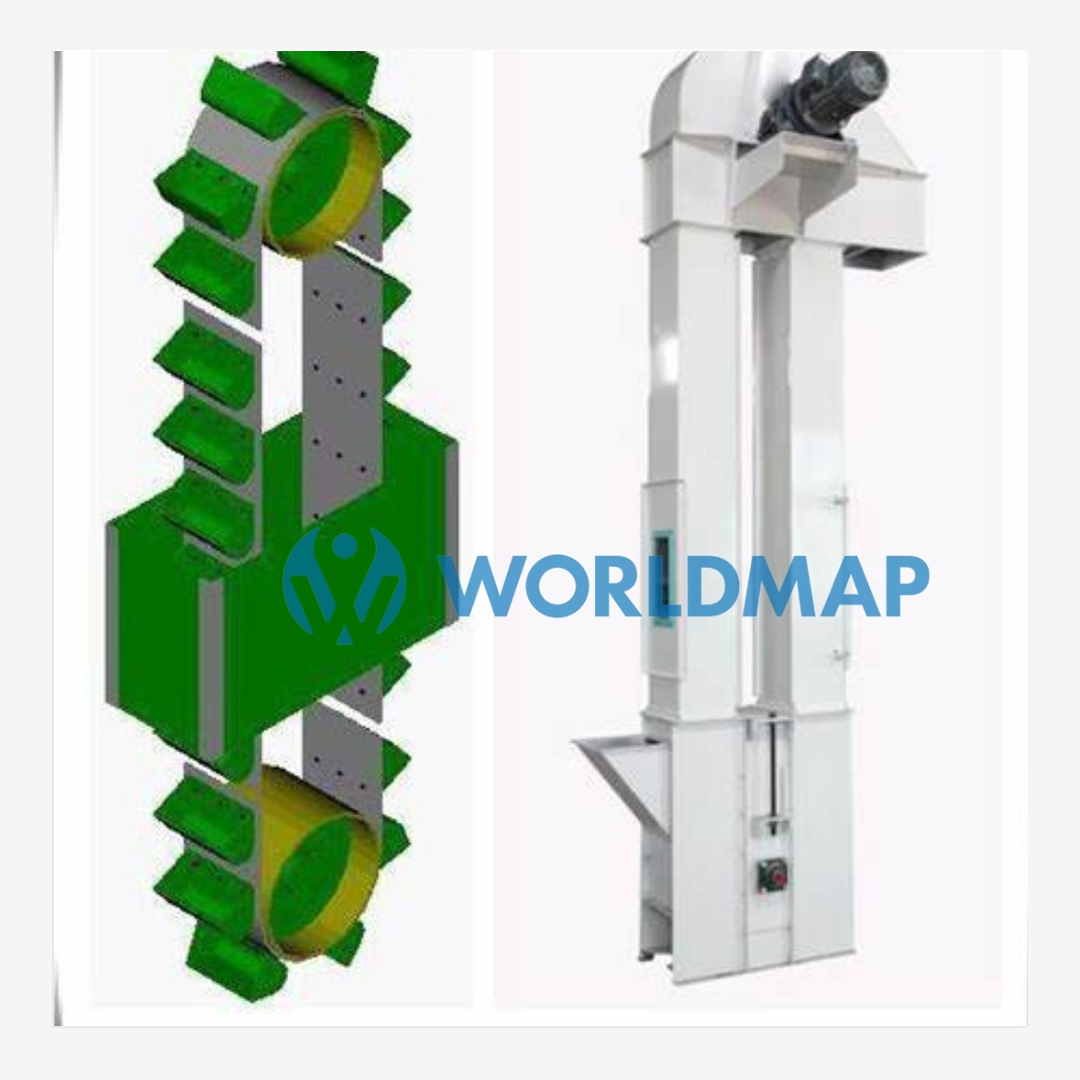

- Bucket Elevator Systems: These are devices that can transport bulk materials to higher levels using buckets connected to a belt or chain. Due to its structure, the transportation of the materials is done vertically. The buckets are produced to lift material from a lower point and move it to a release point. Bucket elevators can be set up for either continuous or batch use and can manage a diverse range of capacities, making them suitable for different industrial uses. Bucket elevators are built strong to perform even in tough conditions, and their enclosed structure safeguards materials from pollution and weather.

- Magnetic Conveyor Systems: They use magnets to transport ferrous materials on a conveyor belt or track. This technology is beneficial for managing metal parts, components, and scrap in manufacturing and recycling settings. The magnetic force keeps the materials in position on the conveyor and decreases the chances of product damage and contamination. Magnetic conveyors are used for different operational needs as they can be designed for various configurations. Magnetic conveyor systems excel in tough conditions, manage heavy loads, and endure wear and tear.

- Vibratory Conveyor Systems: Controlled vibrations are utilized in these systems to move materials along a trough or surface, making them suitable for transporting bulk materials. The motor or electromagnetic drive makes the vibration, which enables accurate regulation of material speed and flow. These systems can be tailored to fit different kinds and dimensions of material, and they can be set up for both horizontal and inclined movement. Vibrating conveyors are advantageous because they provide a steady and even movement of materials, thus avoiding delays in manufacturing operations.

Technical Specifications of Material Handling Conveyor Systems:

Asmaterial handling conveyor system manufacturers, suppliers and exporters in Mumbai, we have added technical datasheet of these systems for more details.

| Specifications | Details |

|---|---|

| Machine Type | Material Handling Conveyor Systems |

| Conveyor Types | Belt, Pneumatic, Bucket Elevator, Slat Conveyor |

| Components | Belt, Rollers, Motor, Side Beds, Control & Drive System |

| Orientation | Horizontal and Vertical |

| Capacity | 50 kg/feet, 1 ton/hr (for bucket elevator) |

| Width | 10 to 20 inch |

| Height | 10 to 20 feet |

| Source | Electric |

| Voltage | 415 V |

| Speed | 60m/min |

| Load Capacity | 200 KG |

| Automation Grade | Automatic or Semi-automatic |

| Material Used | Mild Steel |

| Length | Depends on equipment type |

| Applications | Industrial, Packaging |

Features of Material Handling Conveyor Systems:

As a material handling conveyor system manufacturers in Mumbai, we provide systems with the following features.

- Modularity and customization: These are key features of numerous conveyor systems and make them simple adaptations and expansions to fulfill operational requirements. This feature allows companies to modify their material handling solutions.

- Automation Features: Our offered conveyor systems can incorporate automated control and robotics which helps in decreasing the requirement for manual involvement.

- Versatility: Conveyor systems have the ability to process a diverse range of materials such as bulk items, packages, and delicate products due to their versatility. They can be set up for various transport orientations, like horizontal, inclined, or vertical.

- Safety Measures: Conveyor systems equipped with safety measures like emergency stop buttons, guards, and safety interlocks for the protection of workers and prevent accidents during process.

- Minimal maintenance needs: Our material handling conveyor systems are made for simple maintenance and uncomplicated servicing methods. This leads to decreased operational expenses and less time offline.

Applications of Material Handling Conveyor Systems:

As material handling conveyor system suppliers in Mumbai, following are some applications of it.

- Automotive Industry: Conveyor systems are used in automotive assembly lines and transport parts and components through different production stages.

- Pharmaceutical: In the pharmaceutical sector, conveyors are used for moving raw materials, and finished goods, all within strict adherence to regulatory guidelines.

- Recycling and Waste Management: Conveyor systems are used in recycling plants to move recyclable materials and waste and are easy to sort and process.

- Packaging: Our conveyor systems are widely used in the packaging sector for the movement of products during packaging, labeling, and palletizing stages.

- Construction: In construction areas, conveyors are used to move materials like concrete, gravel, and other large items, while decreasing the need for manual labor.

As the leading material handling conveyor system manufacturers in Mumbai, suppliers and exporters in Mumbai, we at Worldmap Autocontrol System strive to be a global leader in industrial automation, recognized for our innovative solutions, commitment to excellence, and customer care. Our aim is to transform industries by implementing advanced automation systems that enhance efficiency and promote sustainability. Our aim is to set higher standards in the automation industry and enhance the success of our worldwide customers through innovation and customer-centric focus.

FAQs

Material handling supply chain conveyor systems are used to transmit materials from one place to another in numerous industries like pharmaceutical and chemical industries automobile manufacturing e-commerce and retail distribution.

A conveyor system can have a variety of safety measures or alarms for obstructions and system problems such as an emergency stop button. It also uses materials that are resistant to fire and explosion when necessary.

Material handling conveyor systems should typically last between 15 and 30 years if properly maintained. How hard they are used and the working environment have a big impact on how long they last.